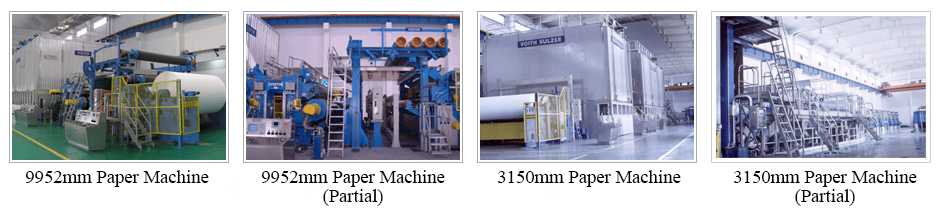

Production equipment

时间:2021-10-27

Since 2001, Minfeng has invested 1.5 billion yuan to build the world’s advanced cigarette paper production line PM 18, the tracing paper production line PM 19, high-grade thin paper production line PM 20, and high-grade coated paper production line PM 21, which were all put into operation in 2004. Over the years, we have continuously integrated innovative technologies and successfully developed new products.

In order to meet the market demand, China’s first high-grade cigarette paper production line – PM 18 was built and put into operation in 2001 at an advanced level in the world. The quality of Minfeng-made cigarette paper can replace that of imported. As China’s first cigarette paper was born in Minfeng in 1936, Minfeng has been at the cutting edge of domestic cigarette paper production ever since, especially with new technology and equipment, large production capacity, and strong competitive advantage nowadays.

In 2002, the tracing paper production line PM 19 was built and put into operation. Owing to technological development, the product has now been widely used in tracing, printing, packaging, arts and crafts, etc. with multiple basis weight and characteristics. At present, the quality of tracing paper series products has taken a giant step into the ranks of the world’s finest.

In 2003, the high-grade thin paper production line PM 20 was put into operation. Equipped with advanced production process automation and quality control systems (QCS), it primarily manufactures tipping base paper, plug wrap paper, cigarette paper, etc.; its product has extensive market coverage in the country.

In 2004, the high-grade coated paper production line 21 was built and put into operation. It is taken as a major national project of technological transformation, which introduced German technical equipment and advanced technical software. Thus, the design idea and equipment configuration of the new production line meet the market demand of producing various kinds of special paper with multiple specifications and grammages to the maximum. Its major products are glassine base paper, vacuum aluminized base paper, wet strength label paper, ordinary and high-grade matte colour inkjet paper, thermal base paper and others.

In 2005, Minfeng introduced a batch of coating machines, supercalenders and rewinders from Switzerland, Finland and Germany, which are equipped with a set of automatic control systems and infrared drying systems that support production line 21. Specifically – guaranteeing the best quality of paper with high smoothness – this production line is suitable for coating, supercalendering and finishing of high-grade vacuum aluminized base paper, glassine and wet strength label paper.

QCS/DCS

l A complete quality control systems (QCS) include scanning, visualization and monitoring paper and process variables and parameters like basis weight, moisture, porosity, ash contents, smoothness, cross profiles, formation, colors and various possible defects. Our QCS systems provide valuable control insights in real-time via remote monitoring and intuitive QCS performance dashboards.

l Distributed Control System (DCS) is focused on general activities in the field of adjustable and constant speed drives and other various motor control systems within the industry.