▷ Materials: wood pulp, flax pulp, bamboo pulp, or specialty fibers ▷ Features: verge, repse, twill, anti-counterfeiting or colored

▷ Grammage: 20gsm - 45gsm ▷ Certifications: FSC; SGS; ISO 9001

▷ Roll Paper for Cigarettes won the National Silver Medal, Third Prize at the National Industrial New Product Exhibition, and Famous Trademark in Zhejiang Province, China.

▷ Packaging tobacco and cigarettes

▷ Alternative to pre-made cigarettes

▷ Crafting and DIY Projects

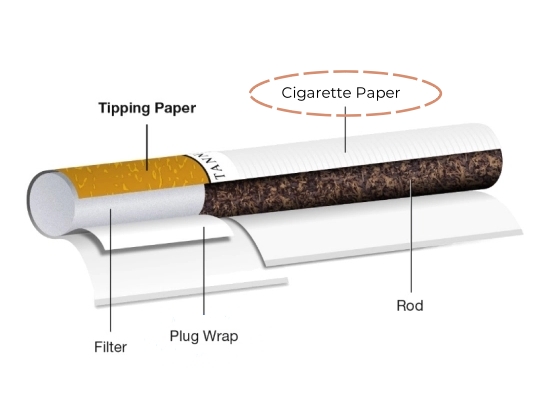

Rolling paper(cigarette paper) is a specialty paper designed to roll tobacco or herbal blends for smoking. It is engineered to burn slowly and evenly while maintaining structural integrity during rolling. Historically, early rolling paper was made from corn husks or rice straws, but modern versions rely on advanced materials like flax and refined wood pulp.

The composition of rolling paper is a delicate balance between natural fibers and scientific additives. Most papers begin with a base of wood pulp, which is bleached for purity and blended with minerals like calcium carbonate to regulate combustion. High-end papers often incorporate flax (linen) fibers, prized for their slow burn and minimal ash. In recent years, eco-conscious brands have turned to hemp or unbleached rice straw, offering a rustic appearance and reduced environmental impact.

Key additives include potassium citrate, a natural salt that acts as a burn retardant, and gum arabic, a plant-based adhesive that seals the paper when moistened. These components ensure the paper ignites predictably, burns smoothly, and adheres effortlessly while remaining safe for inhalation.

The true test of rolling paper lies in the performance. A high-quality sheet must burn at a controlled rate of 1–1.5 centimeters per minute, balancing efficiency with the user’s pace of smoking. Porosity, measured in CORESTA units, determines airflow; papers with 50–100 CORESTA allow just enough oxygen to cool the smoke without harshness. Ash quality is another marker of excellence: pure white ash signals clean combustion, while darker residues may indicate impurities.

Strength is equally vital—the paper must resist tearing during rolling yet dissolve cleanly when burned. Innovations like fire-safe (LIP) papers, mandated in some regions, add a layer of safety by self-extinguishing if left unattended, reducing fire hazards.

Precise technical specifications define rolling paper. Its weight typically ranges from 10 to 30 grams per square meter (GSM), with ultra-thin varieties weighing as little as 12 GSM. Thickness hovers between 20 and 50 micrometers, ensuring minimal interference with the smoking material’s flavor. Standard widths include 70mm for slim cigarettes and 110mm for thicker, cigar-like rolls. Burn time varies by material: flax-based papers can last up to 4 minutes per cigarette, outperforming cheaper wood pulp alternatives.

Adhesives also matter. Plant-based gums, like gum arabic, dominate the market due to their non-toxic properties, though synthetic alternatives exist for mass production. These parameters collectively determine whether the paper feels rustic, luxurious, or utilitarian in the user’s hands.